Aniline Oil / CAS 62-53-3/purity 99.95%/Best Price

Deacription

| Product Name: | Aniline oil |

| Appearance: | colorless oily flammable liquid ,has a strong smell |

| Other name: | Phenylamine / Aminobenzene / Benzamine |

| CAS NO.: | 62-53-3 |

| UN NO.: | 1547 |

| Molecular Formula: | C6H7N |

| Molecular Weight: | 93.13 g·mol−1 |

|

Melting point: |

−6.3 °C (20.7 °F; 266.8 K) |

| Boiling point: | 184.13 °C (363.43 °F; 457.28 K) |

| Water solubility: | 3.6 g/100 mL at 20 °C |

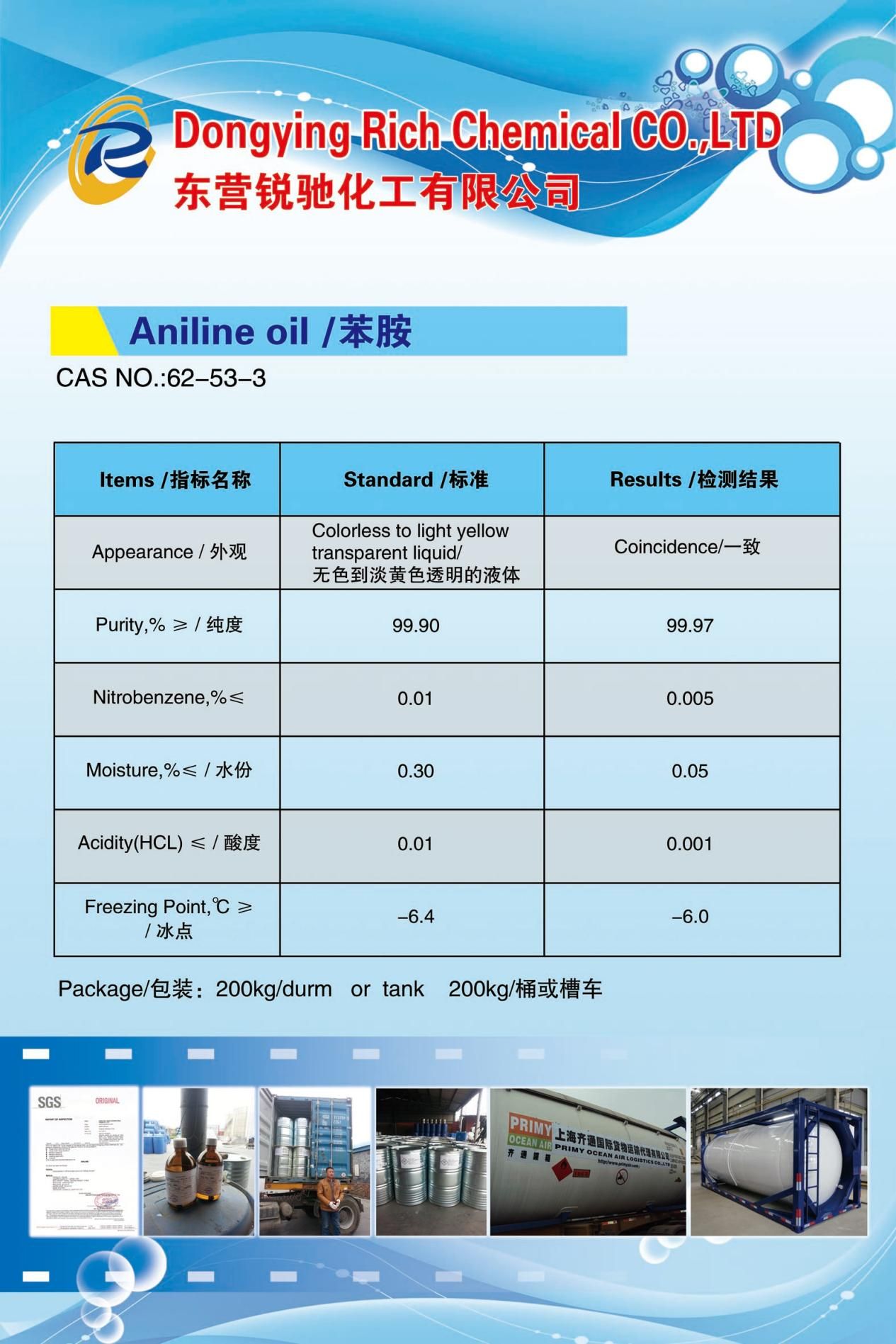

Specification

Product Name: Aniline oil

| Number | Item | Specification |

| 1 | Appearance | Colorless or yellowish oil liquid |

| 2 | Purity | 99.95% |

| 3 | Nitrobenzene | 0.001% |

| 4 | High Boilers | 0.002% |

| 5 | Low Boilers | 0.002% |

| 6 | Water Content by Coulometric KF | 0.08% |

Packing

200kgs/drum, 80 Drums/ 20’FCL 16MT/20’FCL

23MT/ISO Tank

Application

1)Aniline is an organic compound with the formula C6H7N. Aniline is the simplest and one of the most important aromatic amines, being used as a precursor to more complex chemicals.

2) Being a precursor to many industrial chemicals, mainly used is in themanufacture of precursors to polyurethane.

3)The largest application of aniline is for the preparation of methylene diphenyl disocyanate (MDI).

4)The other usages include rubber processing chemicals (9%), herbicides (2%), anddyes and pigments (2%).The principal use of aniline in the dye industry is as a precursor to indigo, the blue of blue jeans.

5)Aniline is also used at a smaller scale in the production of the intrinsically conducting polymerpolyaniline.

Storage

Aniline Oil is a dangerous product, special attention should be paid to the following items when storing:

1. Storage environment: Aniline Oil should be stored in a cool, dry and well-ventilated warehouse, avoid direct sunlight and humid environment. The storage area should be kept away from fire, heat and oxidants to prevent fire and explosion.

2. Packaging: Choose non-leakage, non-damaged and well-sealed containers, such as steel drums or plastic drums, to prevent volatilization and leakage. Containers should be checked for integrity and tightness prior to storage.

3. Avoid confusion: Avoid mixing with other chemicals, especially harmful substances such as acids, alkalis, oxidizing agents, and reducing agents.

4. Operating specifications: Wear protective equipment, including protective gloves, protective glasses and protective masks, during operation to avoid contact with this substance. After operation, the protective equipment should be cleaned and replaced in time to avoid reuse. < 2 years

5. Storage period: It should be managed according to the date of production, and the principle of "first in, first out" should be followed to control the storage period and avoid quality deterioration.